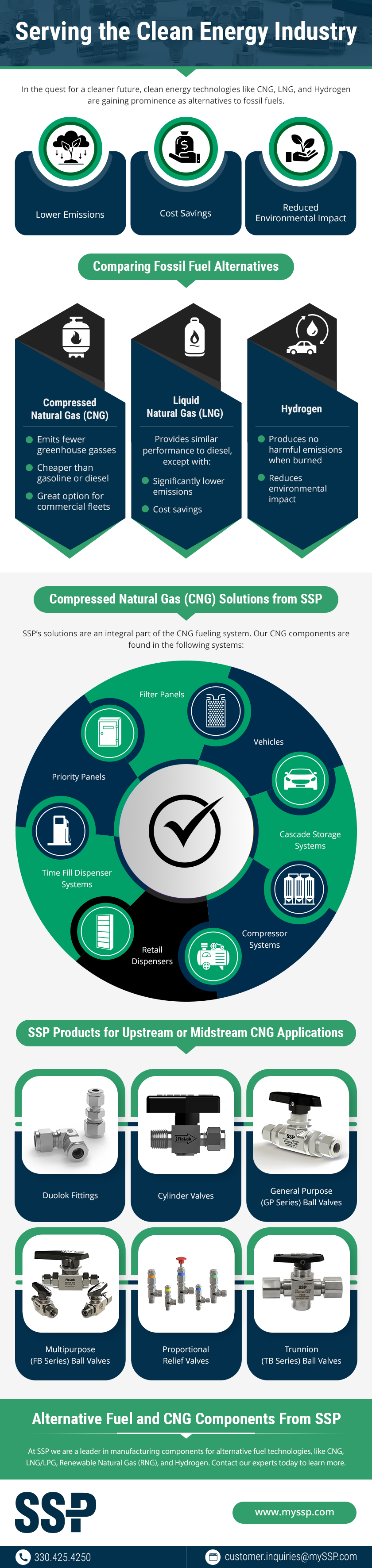

As the world moves towards a cleaner, more sustainable future, clean energy technologies will become increasingly important. Compressed Natural Gas (CNG), Liquid Natural Gas (LNG) and Hydrogen are all used as alternatives to traditional fossil fuels.

CNG and LNG are popular alternative fuel sources in the transportation industry. CNG emits fewer greenhouse gasses and is cheaper than gasoline or diesel, making it a great option for commercial fleets. LNG provides similar performance to diesel but with significantly lower emissions and cost savings. One of the most significant advantages of hydrogen is that it produces no harmful emissions when burned, making it an excellent option for companies looking to reduce their environmental impact.

These clean energy technologies offer numerous benefits, including lower emissions, cost savings, and reduced environmental impact, making them attractive options for companies and individuals looking to embrace a more sustainable future.

CNG Solutions

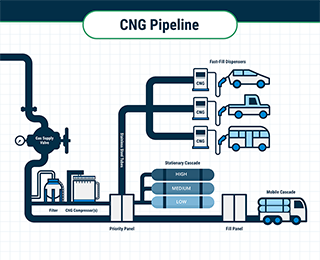

SSP offers solutions as an integral part of the CNG fueling system for various products. Our CNG components are found in the following systems:

-

Vehicles

-

Cascade Storage Systems

-

Compressor Systems

-

Retail Dispensers

-

Time Fill Dispenser Systems

-

Priority Panels

-

Filter Panels

CNG fuel systems are primarily used in small passenger vehicles, public transit buses and semi-trucks. SSP valves and fittings are also suitable for compressors and vehicle fuel stations serving residential and commercial vehicles.

Fittings

The smooth operation of compressed natural gas operations depends on reliable tubing, which is widely used in upstream and midstream applications. To conduct CNG transfer activities, however, tubing needs the proper valves and fittings. A CNG tank will have the highest level of dependability and safety with a tube valve or fitting made for CNG applications. SSP's Duolok fittings are appropriate for CNG applications as well.

Valves

SSP cylinder valves are suitable for CNG and similar gases, including methane and ethane. Our valves include the following:

-

General Purpose (GP Series) Ball Valves: Our GP series ball valves are made to withstand pressures up to 6000 PSIG with a quarter-turn shut-off for leak-tight flow control in CNG applications. The GP series is flexible, allowing for various connections and a range of temperatures.

-

Multipurpose (FB Series) Ball Valves: SSP FB series ball valves offer flexible configuration, low actuating torque, low maintenance, high lifespan, and leak-tight performance at up to 6000 PSIG and a range of temperatures. The FB series is suitable for high-pressure applications, including instrumentation and control systems, equipment, and CNG supply lines.

-

Proportional Relief Valves: Our relief valves are designed to divert flow from pressure-sensitive equipment upstream. Our proportional relief valves offer a leak-tight design and excellent resealing and cracking pressures. It is suitable for various applications with a selection of connections and seal materials.

-

Trunnion (TB Series) Ball Valves: Our high-pressure shut-off and directional control valves. They are suitable for system pressures of up to 10,000 PSIG and a wide range of temperatures.

SSP offers various components, including filters, valves, and fittings for alternative fuel applications. We offer solutions for the following alternative fuels:

-

Liquid Natural Gas (LNG/LPG)

-

Hydrogen

Alternative Fuel and CNG Components From SSP

At SSP we are a leader in manufacturing components for alternative fuel technologies, like CNG, LNG, Renewable Natural Gas (RNG), and Hydrogen. These fuels are revolutionizing the way vehicles and power-generating equipment operate, delivering cleaner and more efficient performance. Our components are specifically designed to meet the challenges posed by these new technologies, ensuring they deliver reliable performance and meet the required industry standards such as ECE R110.

We are ISO 9001:2015 certified, delivering quality products and services quickly and precisely. We work with 350 distributors worldwide and produce our products in the USA from our 165,000-square-foot facility.

Visit our product catalog to see our alternative fuel and CNG components, and contact us or request a quote to learn more.