Residential and industrial energy demand is on the rise. To meet this heightened demand while adhering to increasingly stringent environmental requirements, power plants should seek to optimize their instrumentation systems. An optimized instrumentation system composed of top quality fittings, valves, tubing, and quick connects will ultimately lead to increased energy output, improved fuel efficiency, streamlined costs, reduced outages, and decreased emissions. When selecting instrumentation components for power plant requirements, safety, efficiency, and cost savings are top priorities.

Residential and industrial energy demand is on the rise. To meet this heightened demand while adhering to increasingly stringent environmental requirements, power plants should seek to optimize their instrumentation systems. An optimized instrumentation system composed of top quality fittings, valves, tubing, and quick connects will ultimately lead to increased energy output, improved fuel efficiency, streamlined costs, reduced outages, and decreased emissions. When selecting instrumentation components for power plant requirements, safety, efficiency, and cost savings are top priorities.

At SSP, we are committed to guiding our customers in the power generation industry to improve process efficiency, safety, and costs with superior quality instrumentation components. Read on to learn about our instrumentation components for power plants and related capabilities.

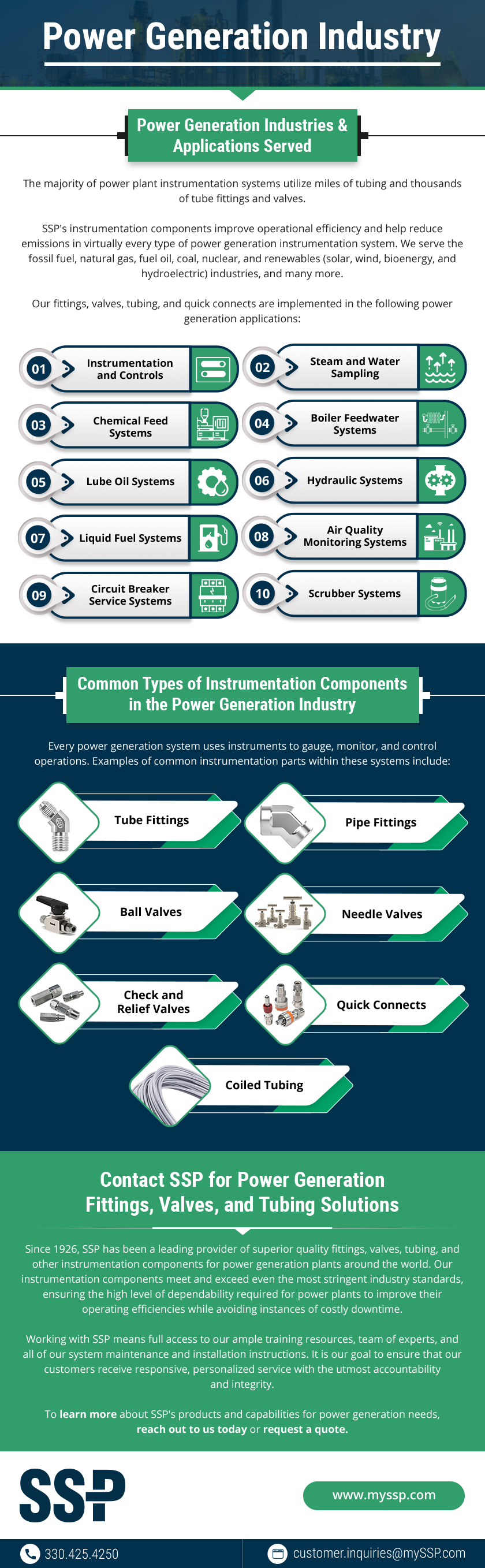

Power Generation Industries & Applications Served

The majority of power plant instrumentation systems utilize miles of tubing and thousands of tube fittings and valves.

SSP's instrumentation components improve operational efficiency and help reduce emissions in virtually every type of power generation instrumentation system. We serve the fossil fuel, natural gas, fuel oil, coal, nuclear, and renewables (solar, wind, bioenergy, and hydroelectric) industries, and many more.

Our fittings, valves, and quick connects are implemented in the following power generation applications:

- Instrumentation and Controls. Power plant systems require instrumentation to monitor and control pressure, temperature, material flow, speed, volume, and direction. Components common in these applications include tubing, ball and needle valves, high-temp valves, check and relief valves, and quick connect.

- Steam and Water Sampling. Steam and water analysis systems (SWAS) remove contaminants in process fluids to prevent corrosion in critical systems using pressure valves, temperature shutoff valves, and pressure relief valves.

- Chemical Feed Systems. Chemical feed systems monitor and adjust pH, chloride, silica, dissolved O2, and solid content of power plant process fluids. Samples are transported in long runs of stainless steel tubing with many fittings and valves.

- Boiler Feedwater Systems. Boiler feedwater systems are used to remove impurities, adjust chemistry, and maximize steam use. Boiler feedwater systems require numerous components, including tube fittings, ball and needle valves, high temp valves, check and relief valves, quick connects, and special alloys.

- Lube Oil Systems. Power generation systems rely on lubrication to ensure safe equipment operation. Lube oil systems use flexible hoses, usually 3/4" and smaller, to lubricate critical equipment.

- Hydraulic Systems. Hydraulic equipment requires long-distance stainless steel tubing between 3/4" and 1" and a variety of safety and pressure valves to ensure safe and efficient operation.

- Liquid Fuel Systems. Power plants that run fuel oil or natural gas typically use durable stainless steel tubing and fittings to move corrosive fuel.

- Air Quality Monitoring Systems. Air quality monitoring systems, also known as continuous emissions monitoring systems (CEMS), are used to constantly measure emissions in the flue, chimney, or other exhaust routes.

- Circuit Breaker Service Systems. Circuit breakers in power plants use SF6 gas to prevent electrical arcs. The gas is corrosive and hazardous, so carts that service circuit breakers incorporate corrosion-resistant stainless steel valves and fittings along with Dielectric Unions.

- Scrubber Systems. Scrubber systems are used in coal plants and waste combustion to remove pollutants from waste gases. These systems require extensive instrumentation, including stainless steel tubing, valves, and quick connect fittings.

Common Types of Instrumentation Components in the Power Generation Industry

Every power generation system uses instruments to gauge, monitor, and control operations. Examples of common instrumentation parts within these systems include:

- Ball Valves. SSP ball valves are used in a wide range of instrumentation for control systems, safety shutoffs, high temperature, and high-pressure applications.

- Needle Valves. SSP provides needle valves for temperature and pressure monitoring instrumentation, controls, fluid testing applications, laboratory equipment, and other applications.

- Check & Relief Valves. SSP's selection of check valves for instrumentation, alternative fuels, and small process applications can withstand pressures up to 6000 psig (413 bar) and temperatures from -100 to 900° F (-73 to 482° C).

- Stainless Steel Coil Tubing. Using one continuous run of tubing eliminates potential leak points, improving system safety and reliability. At SSP, every foot of our stainless steel tubing undergoes 100% hydrostatic testing and positive material identification, ensuring a safe installation and long-term dependability. Our tubing OD, wall thickness, hardness, chemistry and appearance specifications are tighter than industry standards.

- Quick Connects. SSP's quick connects are specifically engineered for fast connection and disconnection of fluid lines without tools. They are ideal for sample systems, venting, draining, mixing, and other applications requiring rapid or frequent connections and disconnections.

Contact SSP for Power Generation Fittings and Valves Solutions

Since 1926, SSP has been a leading provider of superior quality fittings, valves, and other instrumentation components for power generation plants around the world. Our instrumentation components meet and exceed even the most stringent industry standards, ensuring the high level of dependability required for power plants to improve their operating and fuel efficiencies while avoiding instances of costly downtime.

Working with SSP means full access to our ample training resources, team of experts, and all of our system maintenance and installation instructions. It is our goal to ensure that our customers receive responsive, personalized service with the utmost accountability and integrity.

To learn more about SSP's products and capabilities for power generation needs, reach out to us today or request a quote.