Click to Find Catalogs

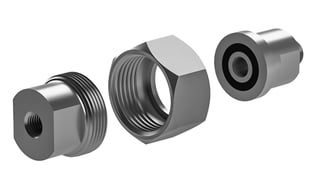

The Soft Seal HP or Q-seal fitting is our most heavy-duty ORFS fitting. It conforms with the requirements of Naval BuShips Series 803 drawings and is also available in additional end styles. It is for gas and liquid applications ranging from vacuum to 6,000 psi at temperatures from -20° F (-10° C) to 225° F (107° C). Q-Seal fittings are considered “ship safe” when used in accordance with ANSI B31.1. The three-piece fitting with universal nut allows almost unlimited combinations of end connections in sizes from 1/8” through 2” in both tubing and pipe. SSP’s Q-Seal can be used interchangeably with CPV’s O-Seal.

Quick Links

Specifications

- Working Pressure: Vacuum to 6000 psig

- Temperature Rating: -10 to 225° F

- Body Materials: 316/316L SS, Alloy 400, Brass

- O-Ring Materials: FKM (Standard), Buna

- Sizes: 1/8 to 2 in.

Design

Soft-Seal tube and pipe fittings seal fluids and gases at very high pressures and vacuum. Each features a high durometer O-Ring held in a precision-machined groove in the fitting body. This elastomeric seal prevents fluids and gases from leaking.

The HP O-Ring face seal fitting assembly consists of four parts: threaded fitting body with O-Ring groove, O-Ring, nut, and tailpiece. The standard O-Ring is Buna-N. Other O-Rings have been tested and are available for special applications

The fitting assembly seals when the bottom of the sleeve or tailpiece, which has been fixed to the tubing, compresses the O-Ring in the face of the threaded fitting body as the fitting nut is threaded onto the external threads on the fitting body. The threading process draws the sleeve into full contact with the face of the fitting.

Type 316 stainless steel is the standard material on all bodies and nuts. Type 316L (low carbon) is used for sleeves / tailpieces. Buna-N is the standard O-Ring material.

Applications

HP Soft-Seal tube and pipe fittings suited for liquid and gas systems having:

- High Pressures up to 6000 psi.

- High vibration. The soft seal absorbs shock better than any metal-to-metal sealing system.

- Frequent disassembly and reassembly. The “zero clearance” system, means you don’t need to spring or pull the tubing to seat the fitting or purge the system. This tube fitting can be disassembled and reassembled many times. Simply replace the O-Ring and tighten it to recommended torque.

- Difficult Installation Conditions: The elastomer soft seal conforms well to irregularities in the fitting face or sleeve. So, while proper technique and handling should be observed during assembly, the tube fitting is forgiving of assembly variation.

How HP Soft-Seal O-Ring Face Seal Fitting Work.

Soft-Seal tube and pipe fittings seal fluids and gases at very high pressures and vacuum. Each features a high durometer O-Ring held in a precision-machined groove in the fitting body. This elastomeric seal prevents fluids and gases from leaking.

The HP O-Ring face seal fitting assembly consists of four parts: threaded fitting body with O-Ring groove, O-Ring, nut, and tailpiece. The standard O-Ring is Buna-N. Other O-Rings have been tested and are available for special applications

The fitting assembly seals when the bottom of the sleeve or tailpiece, which has been fixed to the tubing, compresses the O-Ring in the face of the threaded fitting body as the fitting nut is threaded onto the external threads on the fitting body. The threading process draws the sleeve into full contact with the face of the fitting.

Type 316 stainless steel is the standard material on all bodies and nuts. Type 316L (low carbon) is used for sleeves / tailpieces. Buna-N is the standard O-Ring material.

Suggested Applications for Soft-Seal Tube Fittings

HP Soft-Seal tube and pipe fittings suited for liquid and gas systems having:

- High Pressures up to 6000 psi.

- High vibration. The soft-seal absorbs shock better than any metal-to-metal sealing system.

- Frequent disassembly and reassembly. The “zero clearance” system, means you don’t need to spring or pull the tubing to seat the fitting, or purge the system. This tube fitting can be disassembled and reassembled many times. Simply replace the O-Ring and tighten to recommended torque.

- Difficult Installation Conditions: The elastomer soft-seal conforms well to irregularities in the fitting face or sleeve. So, while proper technique and handling should be observed during assembly, the tube fitting is forgiving of assembly variation.