FB Series ball valves use a unique combination of features to provide leak-tight performance at high and low pressures and temperatures, high cycle-life, low maintenance, low actuating torque, and configuration flexibility.

Specifications

- MAWP: up to 6000 psig (413 bar)

- Temperature Range: -40° to 400° F (-40 to 206° C)

- Flow Coefficients: up to 13.8

- Body Materials: 316 SS

- Seat Material: PEEK

- Oring Material: FKM or Low-Temp NBR O-Rings (LFB only)

- End Connections: Duolok, Unilok, or Griplok tube fitting, NPT tapered and SAE straight pipe thread, and O-Ring face seal

- End Connection Sizes: 1/4 to 1 in. (6 to 16 mm Duolok only)

Quick Links

LFB Series Low-Temperature Ball Valves

LFB low-temperature ball valves are designed with materials selected for applications requiring temperature ratings from -40 to 200°F (-40 to 93°C), pressure ratings up to 6000 psig (414 bar), and flow coefficients up to 13.8.

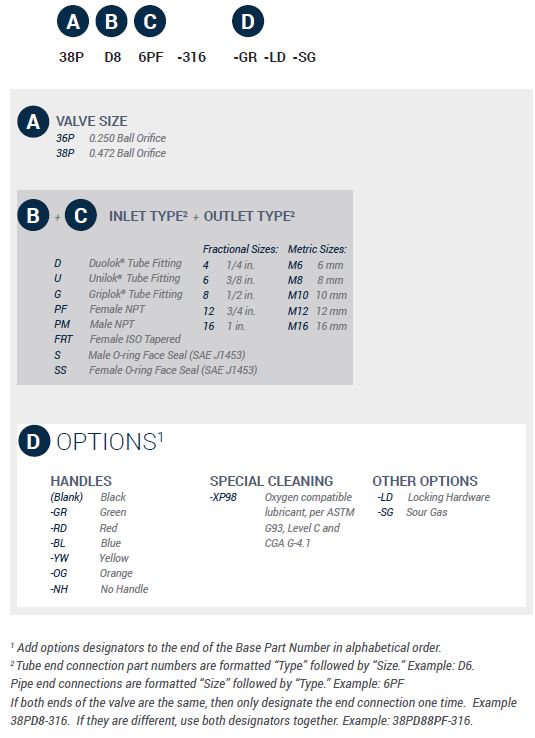

Design

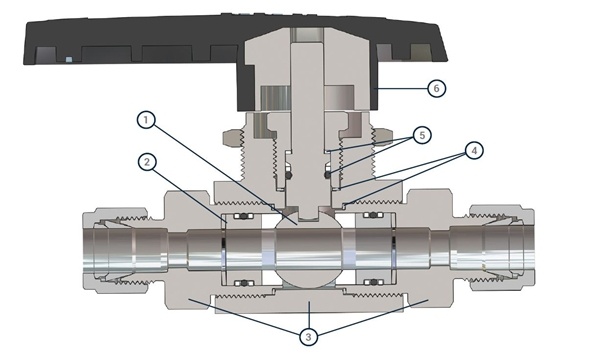

1. FLOATING BALL DESIGN

- Upstream pressure assists sealing against the downstream seat

2. LIVE-LOADED SEATS

- Improve sealing in high, low and dynamic pressure and flow conditions

- Fully supported seats improve cycle-life

- PEEK seats for chemical compatibility and durability

3. END SCREW CONSTRUCTION

- Wide variety of end connection type and size combinations

- Three tube fitting designs

- Easy maintenance

4. ROBUST BODY SEALS

- Leak-tight envelope

5. STEM BEARING AND O-RING STEM SEAL

- Leak-tight seal

- Low actuation torque

- No need for packing adjustments

6. DURABLE DIRECTIONAL HANDLE

- Stainless steel reinforced nylon handle for durability

- Indicates flow direction

- Large ergonomic handle for easier actuation

Applications

FB Series ball valves are very versatile. They can be used in both high and low pressure instrumentation systems, process lines, utility systems, and other applications. Designed for higher pressures than many floating ball valves, they can be used in applications such as high-pressure CNG filling station supply lines, equipment and in instrumentation and control systems. Unlike many floating ball designs, FB Series valves are also suitable for low and dynamic pressure conditions. In addition, end-screw construction allows users to specify a wide variety of end connection size and type combinations.

Temperature – Pressure Table